Choosing the Right Surface Winder for Your Business

Michael Coulson | May 20, 2025

Selecting the Right Surface Winder: A Strategic Investment

Selecting the right surface winder is a high-stakes decision for any business engaged in web converting. A properly specified machine will improve production efficiency, protect material integrity, and reduce operating costs. With a diverse range of configurations and features available, companies must take a structured approach to evaluating key technical and operational factors.

These include material compatibility, roll dimensions, winding architecture, automation levels, slitting methodology, and maintenance requirements. When selected thoughtfully, the right winder not only addresses immediate production needs but also supports long-term scalability, quality assurance, reduced waste, and long-term operational success.

Understanding Material Compatibility for Surface Winders

Material compatibility is the foundation of effective winder selection. The physical characteristics of the substrate—such as tensile strength, elasticity, thickness, and surface sensitivity—determine the mechanical and control requirements of the winding system.

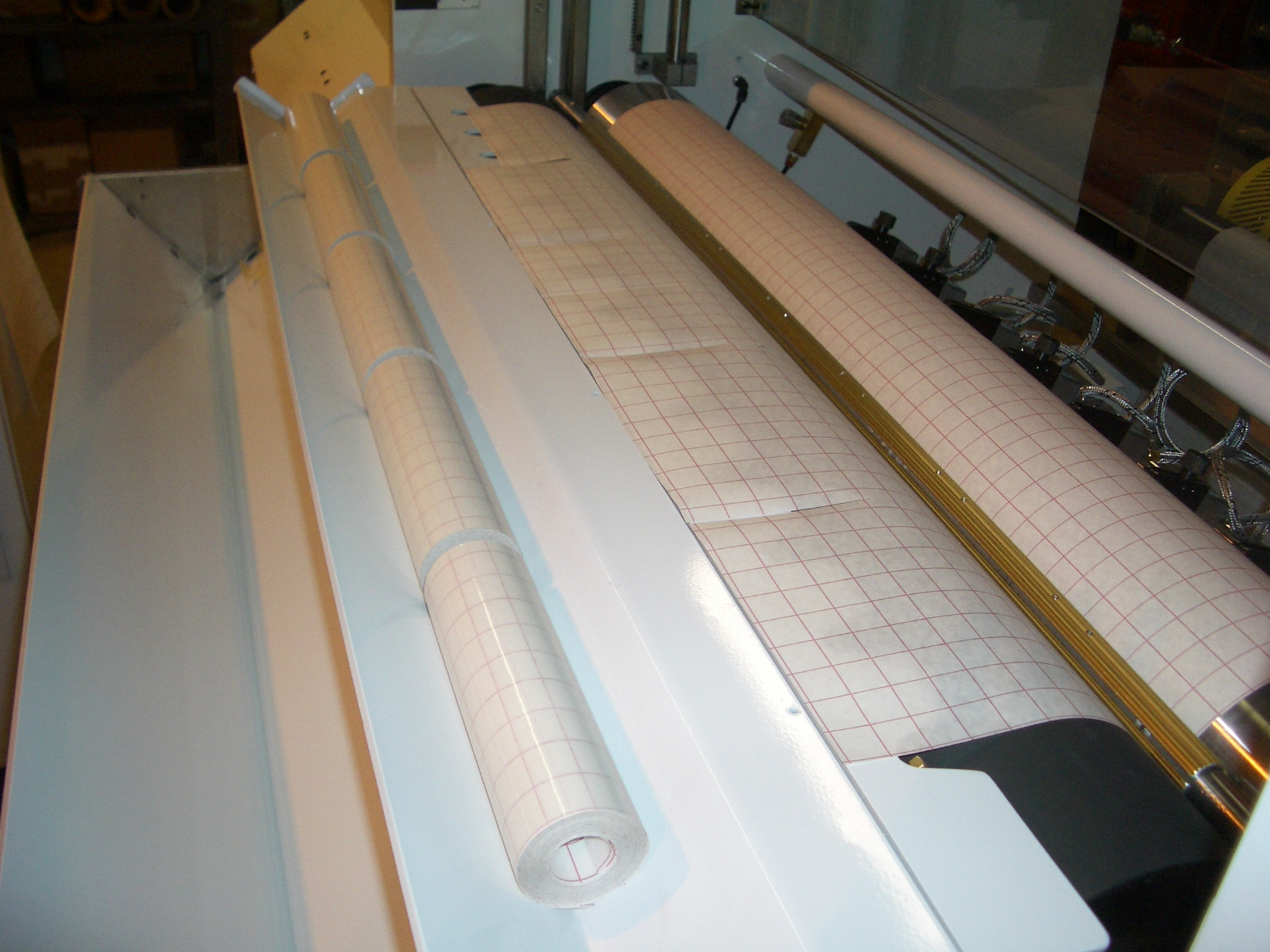

For lightweight materials such as painting paper, counter rolls, and laminates, a winder designed for delicate handling is essential. Heavy-duty materials like paper, board stock, fiberglass mat, and non-wovens require robust winding mechanisms. For high-tension applications, advanced tension management is key to avoid defects like wrinkles or uneven winding.

Determining Web Width and Roll Diameter Requirements

The dimensional range of the winder must align with current and future production needs. Typical surface winders accommodate web widths from 18 to 120 inches and roll diameters from 10 to 90 inches. These parameters impact motor sizing, drive torque, slitting systems, and frame strength.

Selecting a flexible winder ensures adaptability and supports business growth.

Shaft vs. Shaftless Rewinding: Choosing the Best Option

Shafted systems offer precise roll alignment and tension control, ideal for high-speed applications like printing or lamination. Shaftless systems prioritize speed and ease, allowing for faster roll changes and reduced manual handling—perfect for high-throughput environments.

The best choice depends on material properties, operator capacity, and production speed requirements.

Leveraging Automation and Customization Features

Modern surface winders include automation features such as automatic tension control, touchscreen HMIs, and front-unloading configurations. These enhance consistency, reduce manual input, and improve operator safety and training.

Custom features like integrated slitting modules, special tension profiles, or advanced web guiding allow companies to match equipment with their exact needs.

Selecting the Appropriate Slitting Method

Surface winders support score slitting and shear slitting. Score slitting (crush cutting) is best for soft or lightweight substrates, offering simplicity and low cost. Shear slitting delivers high edge quality for dense or fibrous materials like paperboard.

The selection should balance cut precision, material type, maintenance, and throughput.

Evaluating New vs. Used Surface Winders

New winders offer the latest technology, energy efficiency, and OEM support. They minimize startup risks and improve long-term ROI. Used or refurbished units are cost-effective for businesses with budget constraints but require due diligence regarding condition, documentation, and part availability.

Trusted suppliers and full refurbishments can make used machines a smart investment.

Choosing a Reliable Manufacturer for Long-Term Support

Reliable OEMs provide more than machines—they offer partnership. Look for manufacturers that provide custom-engineered solutions, machine rebuilding services, spare parts, and comprehensive support plans.

Long-term technical assistance ensures reliable performance and operational continuity.

Conclusion: Making an Informed Decision

Choosing the right surface winder involves analyzing material compatibility, size, slitting method, automation, and manufacturer reliability. Whether new or used, the goal is to optimize output, quality, and cost-efficiency.

With thoughtful evaluation and the right partner, businesses can make a strategic investment that enhances productivity, reduces waste, and supports long-term success in a competitive industry.

Recent Post

-

Engineering High-Efficiency Converting with Surface Winders

Michael Coulson | May 27, 2025

-

Choosing the Right Surface Winder for Your Business

Michael Coulson | May 20, 2025

-

The Evolution of Surface Winders in Converting Applications

Michael Coulson | May 14, 2025

-

Solving the Machinery Maintenance Crisis—With Phoenix Machine

Michael Coulson | May 1, 2025

-

How to Choose the Right Slitter Rewinder for Your Business

Michael Coulson | March 19, 2025